This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Self-Service Reporting on Supply Chain Data

Senturus developed an agile self-service reporting solution for this built-to-order manufacturer, giving them timely access to critical supply chain data not readily available from their IFS ERP system. Developing an end-to-end analytics architecture, Senturus implemented an Azure data warehouse and Power BI dashboards for reporting. With KPIs easily available to managers and decision makers, the client was able to improve delivery performance, promised delivery date accuracy and product quality.

Challenge

This supplier of custom and pre-built architectural doors and windows had grown through acquisition and was running supply chain analytics off 14 different ERP systems. Pulling reports together was a protracted, manual effort that often left them driving business from the rearview mirror. A report of 11 key metrics took almost nine months to accomplish.

The company decided to consolidate their ERP on IFS. They wanted to modernize their BI and found their reporting capabilities were hampered by the rigid structure of the IFS data mart. The system could not deliver many critical KPIs needed to run their built-to-order business, for instance promised date vs. delivery date metrics. A simple comparison of sales and inventory was not possible without significant heroics in Excel. The manufacturer wanted an interactive, self-service reporting solution that allowed them to evaluate and make key decisions in a timely manner.

Solution

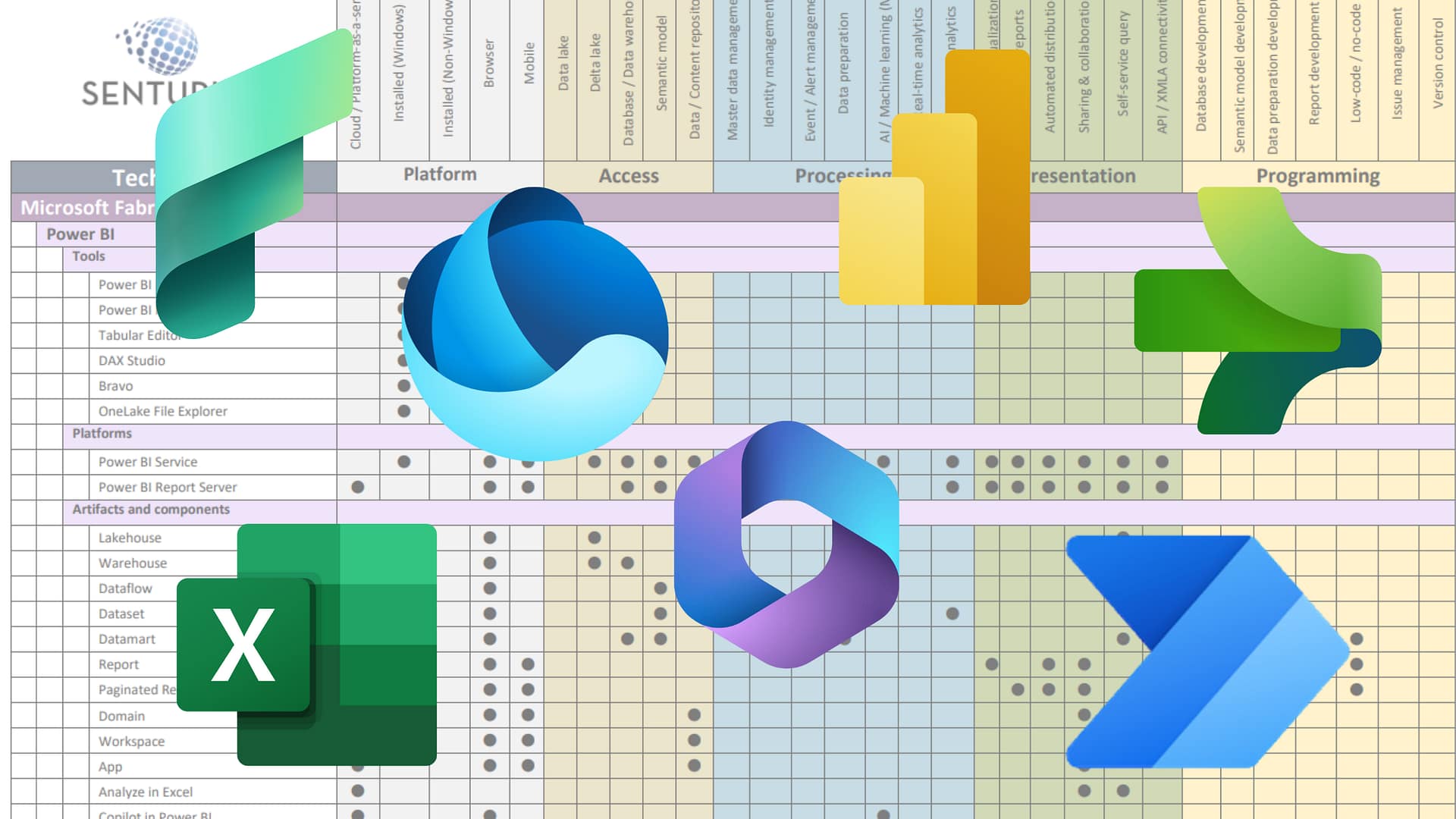

The BI analysis package proved to be insufficient as a reporting tool. Leveraging the data from the IFS ERP system, Senturus designed and built an end-to-end analytics architecture, implementing an extensible Azure data warehouse and Power BI for reporting.

- Performed a full analysis of the company’s business requirements and existing data in order to align business priorities with the optimal supporting BI architecture.

- Assessed and tested the IFS reporting solution against the client’s requirements.

- Identified deficiencies in IFS reporting solution including once-daily data refreshes (not real-time); only summary levels were included; key metrics (e.g., inventory and sales data) were located in separate tables and could not easily be run in the same report.

- Provided suitable architectural options for client consideration; the Microsoft stack (Azure/Power BI was chosen).

- Created a flexible data structure that allowed each manufacturing plant to add their unique data as the IFS instance came online in the phased rollout.

- Modeled the data to facilitate calculations of complex metrics (e.g., delivery performance, inventory levels, supplier quality) and enable functionality including drill down, interactive dashboarding and self-service.

- Built and delivered a series of interactive Power BI dashboards and standard reports.

Benefits

With access to near real-time data and previously difficult-to-procure metrics, the company can identify and swiftly react to disruptions in the supply chain.

- Have timely, accurate reporting of KPIs, including metrics not readily available in IFS.

- Ability to drill down into metrics to determine the cause of supply chain issues.

- Eliminated error prone manual reporting efforts.

- Sped time to insights.

- Graphs in Excel refresh when Power BI does.

- Elevated customer (retailer) service through improved delivery performance, promised delivery date accuracy and product quality.

Technologies

- Azure Data Lake

- Azure Synapse

- Azure Data Factory

- Power BI

- Excel

Easily available KPIs led to improved delivery performance, promised delivery date accuracy and product quality.

About our client

This privately held company is one of the country’s largest suppliers of custom and pre-built architectural doors and windows to a major big box retailer. The company has manufacturing facilities across the US and Canada.